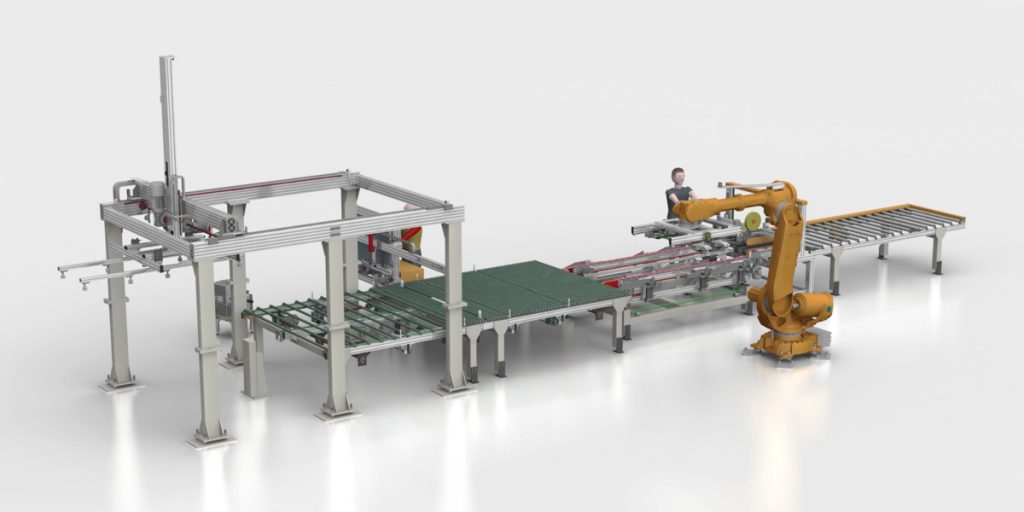

This line is designed to pack single element inside a box standard FEFCO401.

The line is structured in three sections:

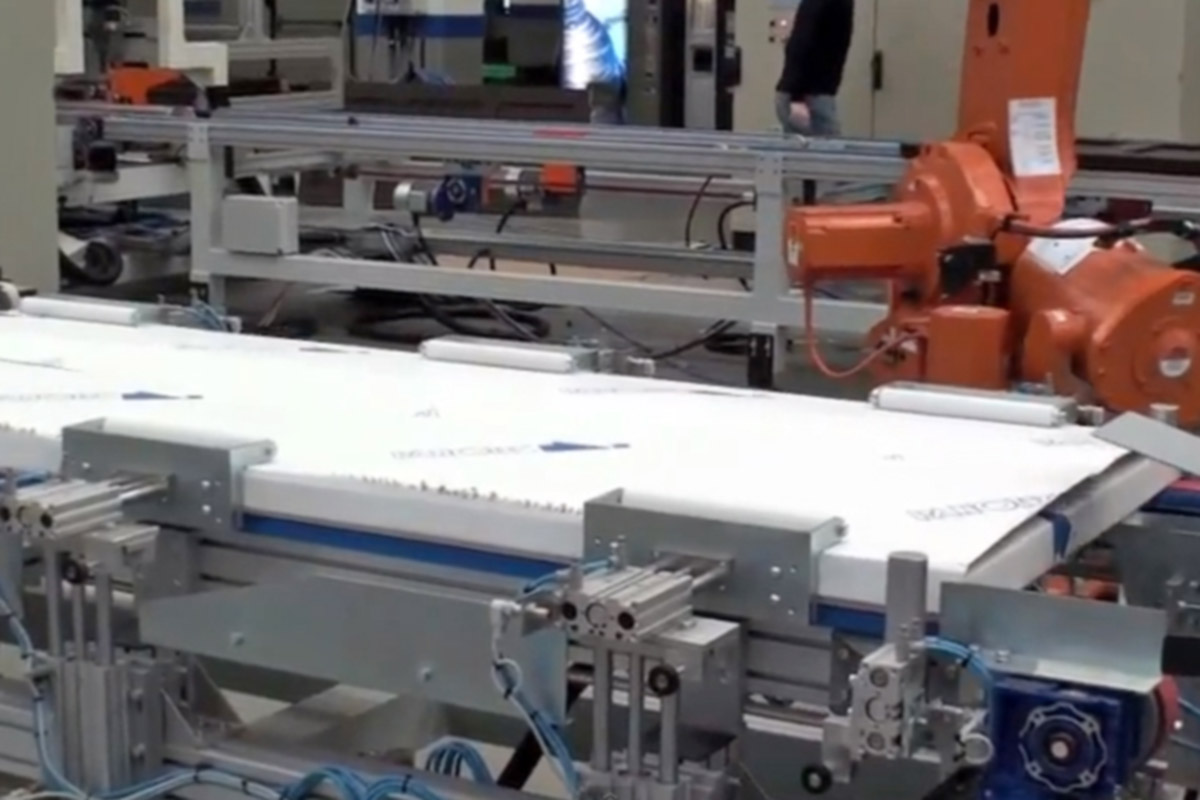

The first one is where the cardboard is fed in manual or automatic in function of optional.

The second is where are positioned the polystyrene or cardboard protection and the doors are fit inside the boxes, manually or automatically, still opened and then the box is erected and folded.

In the third one find place a patented sealing machine that provide to centre closing the boxes by means of tape. This machine start from fixed quote below the box and finish at the same quote on opposite side of box. This allow a perfect closing with much more strength compared to standard sealing machine on market.

At the end the boxes are driven out of the line by a roller conveyor and could be unloaded automatically by robot.

This line is studied to satisfy the medium capacity range and to be much more flexible than traditional line, in fact starting from a simple base configuration could be upgraded with many optional transforming it into a completely automatic line.

The great advantage of this line is the possibility by customer to construct it in function of his current needs and budget with the possibility to make an upgrade schedule step by step during next years without any change on his existing line.

Technical specifications

| Materials | Cardboard FEFCO401 |

| Speed | Up to 4 pcs/min |

Product dimensions

| Length | min 400 – max 2400 mm |

| Width | min 400 – max 1100 mm |

| Thickness | min 25 – max 45 mm |

Benefits

| Maximum flexibility |

| Modular line to be customize in function of customer needs |

| Patented sealing machine |